How Do Ceramic Resistors Work?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors available, ceramic resistors stand out due to their unique properties and applications. This article aims to explore how ceramic resistors work, their composition, advantages, limitations, and their significance in modern electronic devices.

II. Understanding Resistors

A. Basic Principles of Resistance

At the heart of every resistor is the principle of resistance, which is defined as the opposition to the flow of electric current. This concept is encapsulated in Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. Mathematically, this is expressed as:

\[ V = I \times R \]

Resistors are essential components in electronic circuits, as they help regulate current, divide voltages, and protect sensitive components from excessive current.

B. Types of Resistors

Resistors can be broadly categorized into two types: fixed and variable. Fixed resistors have a constant resistance value, while variable resistors, such as potentiometers, allow for adjustable resistance. Additionally, resistors can be made from various materials, including carbon, metal, and ceramics, each offering distinct characteristics.

III. What are Ceramic Resistors?

A. Composition and Materials

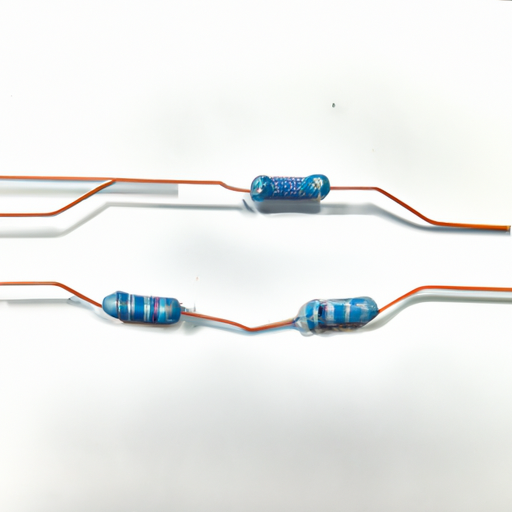

Ceramic resistors are made from a ceramic substrate, which provides excellent thermal stability and mechanical strength. The conductive materials used in ceramic resistors typically include metal oxides, such as tin oxide or ruthenium oxide, which are mixed with the ceramic to create a resistive layer.

B. Types of Ceramic Resistors

Ceramic resistors can be classified into two main types: thick film and thin film resistors.

1. **Thick Film Resistors**: These resistors are created by screen-printing a paste of conductive material onto a ceramic substrate. The paste is then fired at high temperatures, resulting in a thick resistive layer. Thick film resistors are known for their versatility and are commonly used in various applications.

2. **Thin Film Resistors**: In contrast, thin film resistors are made by depositing a very thin layer of conductive material onto a ceramic substrate using techniques like sputtering or evaporation. This results in higher precision and better performance in terms of tolerance and temperature coefficient.

C. Manufacturing Process

The manufacturing process of ceramic resistors involves several steps, including mixing the ceramic and conductive materials, applying the resistive layer to the substrate, and firing the assembly at high temperatures. Quality control measures are implemented throughout the process to ensure that the resistors meet specified performance standards.

IV. How Ceramic Resistors Work

A. Mechanism of Resistance in Ceramic Materials

The resistance in ceramic materials arises from the conductivity of the metal oxides used in their composition. When an electric current passes through the resistor, the metal oxides allow electrons to flow, but they also impede this flow to some extent, creating resistance. The level of resistance can be influenced by temperature and environmental factors, as higher temperatures can increase the conductivity of the metal oxides, thereby reducing resistance.

B. Electrical Characteristics

Ceramic resistors are characterized by their resistance values, which can range from a few ohms to several megaohms, and their tolerances, which indicate how much the actual resistance can vary from the specified value. Additionally, ceramic resistors have power ratings that define the maximum amount of power they can dissipate without overheating. Effective heat dissipation is crucial, as excessive heat can lead to failure.

C. Comparison with Other Resistor Types

Ceramic resistors offer several advantages over other types of resistors, such as carbon or wire-wound resistors. They exhibit excellent thermal stability, high power handling capabilities, and resistance to environmental factors like humidity and corrosion. However, they also have limitations, including sensitivity to mechanical stress and a limited range of resistance values.

V. Applications of Ceramic Resistors

A. Common Uses in Electronic Devices

Ceramic resistors are widely used in various electronic devices, including consumer electronics like televisions, smartphones, and computers. They are also prevalent in industrial applications, where reliability and performance are critical.

B. Specialized Applications

Ceramic resistors are particularly well-suited for specialized applications, such as high-temperature environments, where traditional resistors may fail. They are also used in high-frequency circuits, where their stability and low noise characteristics are advantageous.

VI. Advantages of Ceramic Resistors

Ceramic resistors offer several benefits that make them a popular choice in electronic design:

A. Thermal Stability

Ceramic materials can withstand high temperatures without significant changes in their electrical properties, making them ideal for applications where heat is a concern.

B. High Power Handling Capabilities

Ceramic resistors can handle higher power levels compared to other resistor types, allowing them to be used in demanding applications without overheating.

C. Resistance to Environmental Factors

Ceramic resistors are resistant to humidity, corrosion, and other environmental factors, ensuring long-term reliability in various conditions.

D. Cost-Effectiveness in Mass Production

The manufacturing process for ceramic resistors is well-established and cost-effective, making them suitable for mass production in consumer electronics.

VII. Limitations of Ceramic Resistors

Despite their advantages, ceramic resistors also have some limitations:

A. Sensitivity to Mechanical Stress

Ceramic materials can be brittle and sensitive to mechanical stress, which may lead to cracking or failure under certain conditions.

B. Limited Range of Resistance Values

While ceramic resistors are available in various resistance values, they may not cover the entire range needed for specific applications, limiting their versatility.

C. Potential for Noise Generation

Ceramic resistors can generate noise, particularly in high-frequency applications, which may affect the performance of sensitive circuits.

VIII. Future Trends in Ceramic Resistor Technology

As technology continues to evolve, so does the field of ceramic resistors.

A. Innovations in Materials and Manufacturing

Research is ongoing to develop new materials and manufacturing techniques that enhance the performance and reliability of ceramic resistors. This includes exploring alternative conductive materials and advanced fabrication methods.

B. Integration with Other Electronic Components

Future trends may also see ceramic resistors being integrated with other electronic components, such as capacitors and inductors, to create more compact and efficient circuit designs.

C. Sustainability and Eco-Friendly Practices

With increasing awareness of environmental issues, there is a growing emphasis on sustainability in the manufacturing of electronic components, including ceramic resistors. Efforts are being made to reduce waste and utilize eco-friendly materials in production.

IX. Conclusion

Ceramic resistors play a vital role in modern electronics, offering unique advantages that make them suitable for a wide range of applications. Their thermal stability, high power handling capabilities, and resistance to environmental factors make them a preferred choice in many electronic devices. While they do have limitations, ongoing innovations in materials and manufacturing processes promise to enhance their performance and expand their applications in the future. Understanding how ceramic resistors work is essential for anyone involved in electronics, as they continue to be a fundamental component in the design and functionality of electronic circuits.

X. References

1. "Resistor Basics: Understanding Resistors and Their Applications." Electronics Tutorials.

2. "Ceramic Resistors: Properties and Applications." Journal of Electronic Materials.

3. "Advancements in Resistor Technology." IEEE Transactions on Components, Packaging and Manufacturing Technology.

4. "The Role of Resistors in Electronic Circuits." Electronics Weekly.

This comprehensive overview of ceramic resistors highlights their importance in electronics, providing insights into their functionality, applications, and future trends.